LED / CFL / PCB Glass Fuses 250V 6.3A Subminiature Electric Element

Protection

Subminiature Fuses Quick Detail:

1. Thermoplastic Fuse

2. 300V available

3. Used for power supply,LED,CFL,PCB especially

4. Exact melting time

5. Stronger packing prevent damage when transport

6. Environmental Protection Material

7. Reel packing

Subminiature Fuses Description:

Micro fuse is an electric element protecting electric devices. It

is commonly connected with a circuit in series, and when fault

current increases to a certain value, the fuse blows out to cut off

the circuit so as to fulfill an aim of protecting other equipment

in the circuit. The fuse is the most commonly used component in a

over-current protection circuit. The traditional fuse mainly

consists of two parts of a tube body, of which both ends have metal

connecting terminals, and metal melt in the tube body. The majority

of fuses are cylinder-shaped, namely cartridge construction. But

nowadays, with the fast development of advanced technology, some

special materials are well applied, the fuse industry has started

to move forward in the direction of sub-miniature products and a

series of new products such as Surface Mounted Devices type fuse

are successively developed.

Subminiature Fuses Applications:

Micro Fuse is suitable for various kinds of electronic devices’

circuit over current protection. Widely used in industrial of

Battery Charges, Consumer Electronics, Power supplies, Industrial

Controllers, etc.

Subminiature Fuses Specifications:

1. Subminiature Fuses Standards and Agency Approvals

2.1 Standards:In accordance with IEC60127-1, IEC60127-3 Standard

sheet4, GB9364.1-1997, GB9364.3-1997.

2.2 Subminiature Fuses Certification:

Agency | Ampere Range | Agency File Number |

UR | 50mA ~ 6.3A | E340427(JDYX2) |

C-UR | 50mA ~ 6.3A | E340427(JDYX8) |

VDE | 50mA ~ 6.3A | Pending |

CQC | 50mA ~ 6.3A | CQC11012061981 |

PSE | 50mA ~ 6.3A | Pending |

KTL | 50mA ~ 6.3A | Pending |

2. Subminiature Fuses Product Marking

Micro fuses shall have the following markings:

Example:

Note:

Size and position of the markings shall not be provided.

3. Subminiature Fuses Appearances and Configuration

3.1 There shall not be any remarkable stain, rust or crack on the

appearances,

Markings shall be easily legible.

3.2 Configuration:Radial leaded Sub-Miniature Fuse.

3.3 Color: Black or brown.

4. Subminiature Fuses Dimensions and Structure

5. Subminiature Fuses Material Details

NO. | Part Name | Material |

1 | Cap | Black or Brown Thermoplastic Polyamide PA 6.6, UL 94 V-0 |

2 | Base | Black or Brown Thermoplastic Polyamide PA 6.6, UL 94 V-0 |

3 | Fuse element | Alloy |

4 | Lead wire | Copper, Tin-plated |

6. Subminiature Fuses Product Characteristics

6.1 Lead Pull Strength

10N for 10±1 Seconds

6.2 Lead Thrust Strength

2N for 10±1 Seconds

6.3 Solder ability

Wave : 260℃,≤3s;

Soldering Iron: 350±10℃,≤1s.

6.4 Soldering Heat Resistance

Wave : 260℃,10s;

Soldering Iron: 350℃,3s.

7. Subminiature Fuses Electrical Characteristics

7.1 Test Condition

All electrical test is to be conducted with the ambient air at a

temperature of 25±5℃.

7.2 Pre-Arcing Time / Current Characteristic(limits)

Rating | Blowing Time |

210% | 2 min Max |

275% | 400 ms~10 s |

400% | 150 ms~3 s |

1000% | 20 ms~150 ms |

7.3 Interrupting Rating:

Breaking Capacity: 35A or 10In whichever is greater.

After the test, the insulation resistance value is greater than

0.1ΜΩ

7.4 Rising Temperature Test:

Testing with 1.5In for 15 minutes, then increase 0.1In every 15

minutes.

When fuse opened, any part of measured temperature rise shall not

exceed 135℃, and the ambient temperature of 25 ± 5℃.

8. Subminiature Fuses Environmental Characteristic

8.1 Operating Temperature

-55℃~+125℃.

8.2 Stock Condition

Humidity:Relative humidity ≤ 75% store 3 years average.

8.3

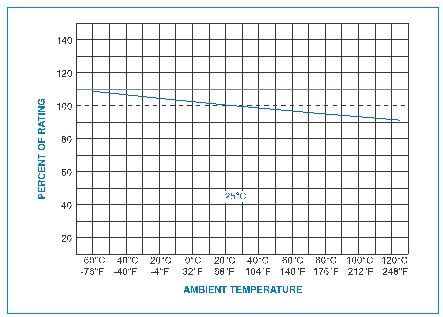

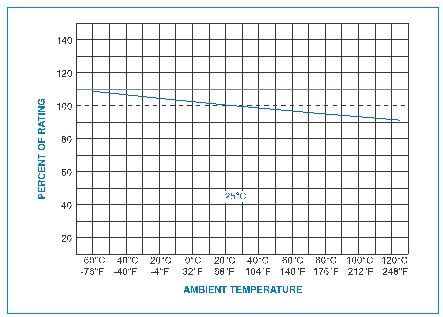

When choosing the fuse's specification, if the operating

environmental temperature beyond the scope from 20~30℃, engineer

should consider the environmental temperature's affection to fuses.

Please refer: Subminiature Fuses Temperature Rerating Curve:

9. Subminiature Fuses Installation Recommendations

9.1 Propose installation way as following picture.

9.2 Recommended Soldering Parameters

A. Wave Parameters:

Solder Pot Temperature: 260℃ Max

Solder Dwell Time: 2~5s

B. Hand-Solder Parameters:

Solder Iron Temperature: 350±5℃

Heating Time: 1~2 s Max

10. Subminiature Fuses Packaging

10.1 The following items indicated on the label:

Catalog number, ratings (voltage, current), interrupting type and

safety mark.

The packing material conforms to ROHS/REACH/HF environmental

protection request. And the packing materials will not have the

chemical reaction with the components.

10.2 Packing Quantity

A: Taping package 1000 pcs per box

B: Bulk 500 pcs / poly bag

4 poly bags / box, altogether 2000 pcs

11. Others

11.1 In the event that an impropriety is found beyond this

specification, it shall be fixed by mutual agreement between the

parties.

11.2 In the event that an impropriety is found in this

specification, Dongguan Uchi ELECTRONIC CO., LTD. shall amend it by

mutual agreement between the parties.

Competitive Advantage:

1. Factory supply directly

2. Completed certificates such as UL,VDE,TUV,etc and high quality

available

3. Quick delivery

4. Best after-sales services

5. OEM & ODM available

Certificates